In the fast-paced, competitive business environment, efficiency and productivity are key factors that determine a company’s success or failure. This is especially true in the packaging and shipping sectors, where the ability to effectively protect products and keep costs low is critical. Therefore, many companies are turning to industrial air cushion machines as a solution.

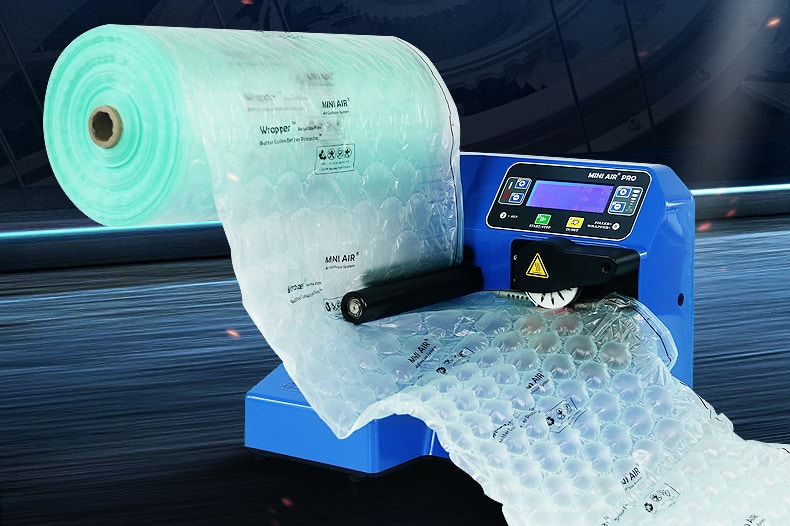

These machines are designed to produce air cushions that fill void spaces and provide cushioning and protection during transportation. A high-quality industrial air cushion machine can significantly increase productivity, reduce product damage, and save money on packaging materials. However, with so many options on the market, choosing the right machine can be a daunting task. In this article, we will discuss some important factors to consider when choosing an industrial air cushion machine and explore the features of the MINI AIR PRO 2, a popular machine manufactured by Ameson Packaging.

First and foremost, consider the specific needs and requirements of your business. Assess the quantities and types of products you ship regularly and the shipping conditions they face. This will help you determine the required capacity and performance of your air mattress machine. MINI AIR PRO 2 is a versatile machine that offers multiple functions to meet various packaging needs.

A key factor to consider is the speed of the machine. MINI AIR PRO 2 has an amazing speed of 25 meters per minute, enabling efficient production and packaging. By choosing a high-speed machine, you can significantly increase productivity and meet tight deadlines.

Another important aspect is the type of film the machine can handle. MINI AIR PRO 2 supports multiple types of films, including inflatable pillow film, bubble film, and bubble mailer film. This versatility ensures that you can use the machine for different packaging materials depending on the specific requirements of your product.

Ease of use is also an important consideration. MINI AIR PRO 2 adopts intelligent sensing technology and automatically stops when there is no film, making it effortless to operate. In addition, it can automatically match various types of films with one click, reducing the time and effort required to switch packaging materials.

Adjustability of speed and inflation is another key factor. MINI AIR PRO 2 allows users to adjust the speed and volume of air cushions produced, providing flexibility and control over the packaging process. This feature is especially useful for fragile or delicate products that require extra cushioning.

Additionally, consider the machine’s compatibility with other packaging equipment you already own or plan to use in the future. MINI AIR PRO 2 easily attaches to top hoppers, winders, baskets and under-table baskets. This versatility ensures seamless integration with your existing packaging setup, increasing overall efficiency.

Choosing the right industrial air cushion machine isn’t just about the machine itself, it’s also about the company behind it. Aimeisen Packaging is a professional manufacturer of air cushion machines with a good reputation. Their MINI AIR PRO 2 machines are exported to more than 100 countries around the world, which is a testament to the quality and reliability of their products.

In summary, choosing the perfect industrial air cushion machine requires careful consideration of your specific needs as well as the machine’s features and capabilities. The MINI AIR PRO 2 offered by Ameson Packaging ticks all the boxes with its impressive speed, versatility in handling different film types, ease of use, adjustability and compatibility with other packaging equipment. By investing in the right machinery, you can increase productivity, reduce product damage, and stay ahead of the competition in the highly competitive packaging and shipping world.